The Automotive Wire Gauge Chart provides data on wire diameter, amperage, and AWG wire sizes for automotive applications. It helps determine the appropriate wire size for specific electrical needs.

This chart is a valuable resource for selecting the right wire gauge to ensure efficient and safe electrical connections in vehicles. By referencing the Automotive Wire Gauge Chart, individuals can confidently choose the correct wire size based on factors such as amperage requirements and wire length.

This tool simplifies the process of selecting the most suitable wire gauge for various automotive wiring projects, contributing to optimal performance and safety.

Credit: autowiringpro.com

Table of Contents

Introduction To Automotive Wiring

Explore the Automotive Wire Gauge Chart to determine the appropriate wire size for your vehicle’s electrical needs. Ensure safety and efficiency by selecting the correct gauge for optimal amperage and performance. Make informed decisions for your automotive wiring projects with this essential tool.

The Role Of Wiring In Vehicles

Wiring is an essential component of any vehicle, responsible for transmitting power and signals to various parts of the vehicle. It connects different electrical components such as lights, sensors, and motors, to the battery and the engine, ensuring the smooth functioning of the vehicle. The wiring system is also responsible for providing power to the different electronic gadgets and accessories present in a vehicle, such as the audio system, GPS, and mobile charging points.

Importance Of Correct Wire Gauge Selection

Selecting the correct wire gauge for automotive wiring is crucial to ensure the safety and reliability of the vehicle. The wire gauge determines the amount of current that can safely flow through the wire without overheating or causing a fire.

Choosing a wire with too small a gauge can lead to overheating and damage, while selecting a wire with too large a gauge can result in unnecessary weight and cost. Therefore, it is important to refer to the automotive wire gauge chart and select the correct wire gauge for each application.

Automotive Wire Gauge Chart

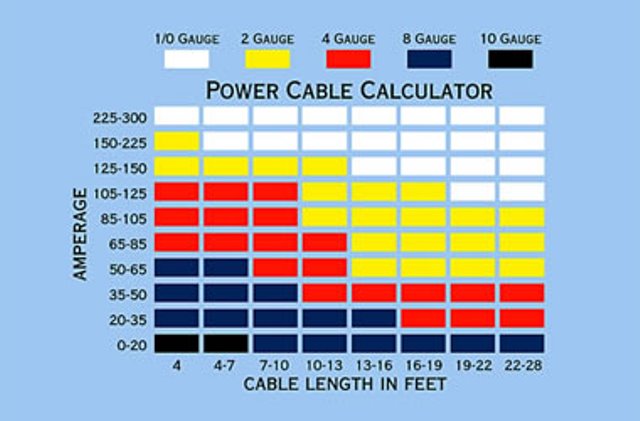

The automotive wire gauge chart provides information on the physical diameter, amperage, and amp rating of different wire gauges. It is available in various formats, such as printable wire gauge chart, wire gauge chart metric, and AWG to mm wire gauge conversion chart. Some of the popular sources for the automotive wire gauge chart include Waytek, Big Jeff Online Inc, and Jasco Automotive Ltd.

Additionally, there are wire sizing chart calculators available online that take into account load current, temperature, wire length, and voltage drop to determine the correct wire size for automotive applications. In conclusion, understanding the role of wiring in vehicles, the importance of correct wire gauge selection, and referring to the automotive wire gauge chart are crucial for the safety and reliability of any vehicle.

Credit: www.sherco-auto.com

Basics Of Wire Gauge

Understanding the basics of wire gauge is essential when it comes to automotive wiring. The wire gauge, also known as the American Wire Gauge (AWG), is a standardized wire sizing system used for gauging the diameter of electrically conducting wire. It’s crucial to comprehend the terminology and differences in wire gauge standards to ensure the safe and efficient flow of current in automotive applications.

Understanding Wire Gauge Terminology

Before delving into the differences in wire gauge standards, it’s important to grasp the terminology associated with wire gauge. The wire gauge is inversely related to the diameter of the wire, meaning that the higher the gauge number, the smaller the diameter of the wire. For instance, a 10-gauge wire has a larger diameter than a 16-gauge wire. Understanding this relationship is vital for selecting the appropriate wire gauge for specific automotive applications.

Differences In Wire Gauge Standards

When it comes to wire gauge standards, it’s essential to recognize that there are multiple standards in use, including the AWG standard and the metric wire gauge standard. The AWG standard is predominantly used in North America, while the metric wire gauge standard is prevalent in many other parts of the world. It’s crucial to be cognizant of these differences to ensure compatibility and compliance with the appropriate standards when selecting and using wire for automotive purposes.

Determining Wire Gauge Needs

When working on automotive wiring projects, determining the appropriate wire gauge is crucial for ensuring safety and optimal performance. To do this effectively, it’s essential to consider various factors that can impact the gauge requirements and understand how to calculate the optimal wire size for specific applications.

Factors Affecting Gauge Requirements

Several factors influence the wire gauge needed for automotive wiring projects. These include the length of the wire, the maximum current flow, and the type of electrical load. Additionally, considering the voltage drop over the length of the wire is critical to ensure that the selected wire gauge can handle the electrical load without significant power loss.

Calculating Optimal Wire Size

To calculate the optimal wire size for automotive applications, the American Wire Gauge (AWG) table is a valuable resource. By cross-referencing the current capacity and the length of the wire, it’s possible to determine the most suitable wire gauge for a specific project. Moreover, utilizing online wire size calculators that take into account load current, temperature, wire length, and voltage drop can provide precise recommendations for selecting the right wire gauge.

Wire Gauge And Amperage

When it comes to automotive wiring, understanding the relationship between wire gauge and amperage is crucial for ensuring safety and optimal performance. The wire gauge determines the amount of current that can safely pass through the wire, making it essential to select the appropriate gauge for specific applications.

In this section, we will explore the amperage capacity of different wire gauges and the importance of matching wire gauge to circuit amperage.

Amperage Capacity Of Different Gauges

Matching the wire gauge to the specific amperage requirement is vital to prevent overheating and potential damage to the electrical system. The following table illustrates the amperage capacity of different wire gauges:

| Wire Gauge (AWG) | Amperage Capacity |

|---|---|

| 20 | 3.5A |

| 18 | 7A |

| 16 | 10A |

| 14 | 15A |

| 12 | 20A |

| 10 | 30A |

Matching Wire Gauge To Circuit Amperage

When selecting the appropriate wire gauge for a circuit, it’s essential to match the wire’s amperage capacity to the specific requirements of the electrical components it will be powering. Utilizing a wire gauge that is too small for the circuit’s amperage can lead to overheating and potential safety hazards, while using a gauge that is excessively large may result in unnecessary added cost and complexity.

It is critical to adhere to the recommended wire gauge based on the circuit’s amperage to ensure optimal functionality and safety.

Automotive Wire Gauge Chart Explained

Reading A Wire Gauge Chart

When referencing an automotive wire gauge chart, it’s essential to understand how to interpret the information it provides. The chart typically lists wire gauge sizes alongside their corresponding diameters and ampere ratings. The smaller the gauge number, the thicker the wire and the higher its ampere capacity. For instance, a 10-gauge wire is thicker than a 12-gauge wire and can handle a higher current.

Applications For Various Wire Sizes

Understanding the applications for various wire sizes is crucial for ensuring safe and effective wiring in automotive systems. Larger gauge wires, such as 10 AWG or 12 AWG, are suitable for high-amperage applications like power distribution to starter motors and battery connections.

On the other hand, smaller gauge wires, such as 16 AWG or 18 AWG, are more appropriate for low-amperage circuits like lighting and accessories.

Metric Conversion For Wire Gauges

When working with automotive wiring, it’s essential to understand the metric conversion for wire gauges. Whether you’re dealing with American Wire Gauge (AWG) or millimeter measurements, having a clear understanding of these conversions is crucial for ensuring the right wire size for your automotive applications.

Understanding Awg To Mm Conversions

When it comes to understanding AWG to mm conversions, it’s important to note that as the AWG number decreases, the wire diameter increases, and vice versa. For instance, a 10 AWG wire has a larger diameter than a 12 AWG wire. To simplify this conversion, refer to the following table:

| AWG | Diameter (mm) |

|---|---|

| 10 | 2.588 |

| 12 | 2.053 |

| 14 | 1.628 |

| 16 | 1.291 |

| 18 | 1.024 |

Using Metric Wire Gauge Charts

Utilizing metric wire gauge charts can simplify the process of selecting the right wire size for your automotive needs. These charts provide a quick reference to determine the appropriate wire diameter based on the AWG or millimeter measurements.

When consulting these charts, consider the specific amperage requirements and the length of the wire to ensure optimal performance and safety for your automotive electrical systems.

Wire Gauge Selection For Specific Applications

When it comes to automotive applications, selecting the right wire gauge is crucial for ensuring optimal performance and safety. Different vehicle systems and components require specific wire gauges to handle the electrical load effectively. Let’s explore the wire gauge selection for specific applications in automotive wiring.

Choosing Wire For Audio Systems

For automotive audio systems, it’s essential to pick the right wire gauge to deliver the necessary power to the speakers and amplifiers. Using thicker gauge wires, such as 12 or 14 AWG, is ideal for long speaker wire runs to minimize power loss and maintain audio quality. On the other hand, smaller gauge wires like 18 or 16 AWG can be suitable for shorter runs or low-power applications.

Picking The Right Gauge For Lighting

When it comes to automotive lighting, choosing the appropriate wire gauge ensures the efficient delivery of power to the lights. Higher wattage bulbs may require larger gauge wires, such as 14 or 12 AWG, to handle the increased current flow without overheating. For low-power or LED lighting, smaller gauge wires like 18 or 16 AWG can suffice.

Temperature Factors Affecting Wire Choice

Choosing the right wire gauge for automotive applications is crucial. Factors like temperature affect wire choice. Refer to an Automotive Wire Gauge Chart for accurate sizing to ensure safe and efficient electrical connections in vehicles.

Impact Of Temperature On Wire Performance

Automotive wires are designed to carry electrical current from one point to another, but their performance can be affected by a range of factors. One of the most significant factors is temperature, which can impact the wire’s electrical conductivity, insulation properties, and overall durability.

When a wire is exposed to high temperatures, it can cause the insulation to melt or degrade, resulting in a short circuit or other electrical problems. To ensure that the wires in your automotive system can withstand high temperatures, it’s essential to choose wires that are rated for the expected operating conditions.

This means selecting wires that have appropriate insulation materials, thickness, and wire gauge for the specific application.

Selecting Wire For Extreme Conditions

Extreme temperature conditions can pose a significant challenge for automotive wiring systems. Whether you are dealing with high or low temperatures, it’s essential to choose wires that are designed to operate effectively in these conditions.

One way to ensure that you are using the right wire for extreme conditions is to consult an automotive wire gauge chart. This chart can help you determine the appropriate wire gauge for the expected current load and temperature range.

Additionally, you may want to consider using wires with high-temperature insulation materials or even custom-designed wire solutions for particularly challenging applications. When selecting wires for extreme conditions, it’s essential to consider all of the factors that can impact wire performance, including temperature, current load, and other environmental factors.

By selecting the right wires, you can ensure that your automotive system will operate reliably and safely under even the most challenging conditions.

Tools For Measuring Wire Gauge

When it comes to working with automotive wiring, having the right tools for measuring wire gauge is essential for ensuring proper connections and preventing electrical issues.

Using A Wire Gauge Tool

Wire gauge tools come in various forms, from simple handheld gauges to digital devices that provide precise measurements. To determine the gauge of a wire accurately, place it in the designated slot on the tool and check the corresponding gauge value displayed.

Tips For Accurate Measurement

- Ensure the wire is clean and free of any debris that could affect the measurement.

- Hold the wire straight and flat against the gauge tool for a precise reading.

- Double-check the measurement to confirm accuracy before proceeding with any connections.

Credit: www.onallcylinders.com

Safety Considerations And Best Practices

When working with automotive wire gauge charts, it is crucial to prioritize safety considerations and follow best practices. By adhering to these guidelines, you can prevent potential hazards and ensure the longevity of your electrical system.

Preventing Overloading And Short Circuits

- Avoid exceeding the maximum amperage capacity for the wire gauge used.

- Use appropriate fuses to protect the circuit from overloading.

- Securely fasten wires to prevent chafing and potential short circuits.

- Regularly inspect wires for signs of wear or damage.

Maintenance And Inspection Tips

- Periodically check wire connections for tightness to prevent voltage drops.

- Clean wire connections to ensure proper conductivity.

- Inspect wires for any signs of corrosion or overheating.

- Replace damaged wires promptly to avoid electrical issues.

Frequently Asked Questions

What Gauge Wire To Use For Automotive?

Choose the correct wire gauge for automotive applications based on the amp rating of the system.

How Many Amps Can 14 Gauge Automotive Wire Handle?

A 14 gauge automotive wire can handle up to 15 amps of current safely.

How Many Amps Can 12 Gauge Wire Handle 12v?

A 12 gauge wire can handle up to 20 amps at 12 volts. It is important to choose the right wire gauge for your automotive wiring needs to prevent overheating and electrical issues. Use an automotive wire gauge chart or consult a professional for guidance.

What Is 16 Gauge Wire Used For In Cars?

16 gauge wire in cars is commonly used for speaker wiring, power accessories, and lighting. It can handle up to 13 amps of current, making it suitable for various automotive electrical applications.

What Is Automotive Wire Gauge Chart Used For?

Automotive wire gauge chart helps determine appropriate wire thickness for vehicle electrical systems.

Conclusion

Understanding the automotive wire gauge chart is crucial for safe and efficient wiring. Proper wire sizing ensures optimal performance and prevents potential hazards. Referencing the wire sizing chart simplifies selecting the right wire gauge for automotive applications. Stay informed and prioritize safety in your vehicle’s electrical system.

Leave a Reply